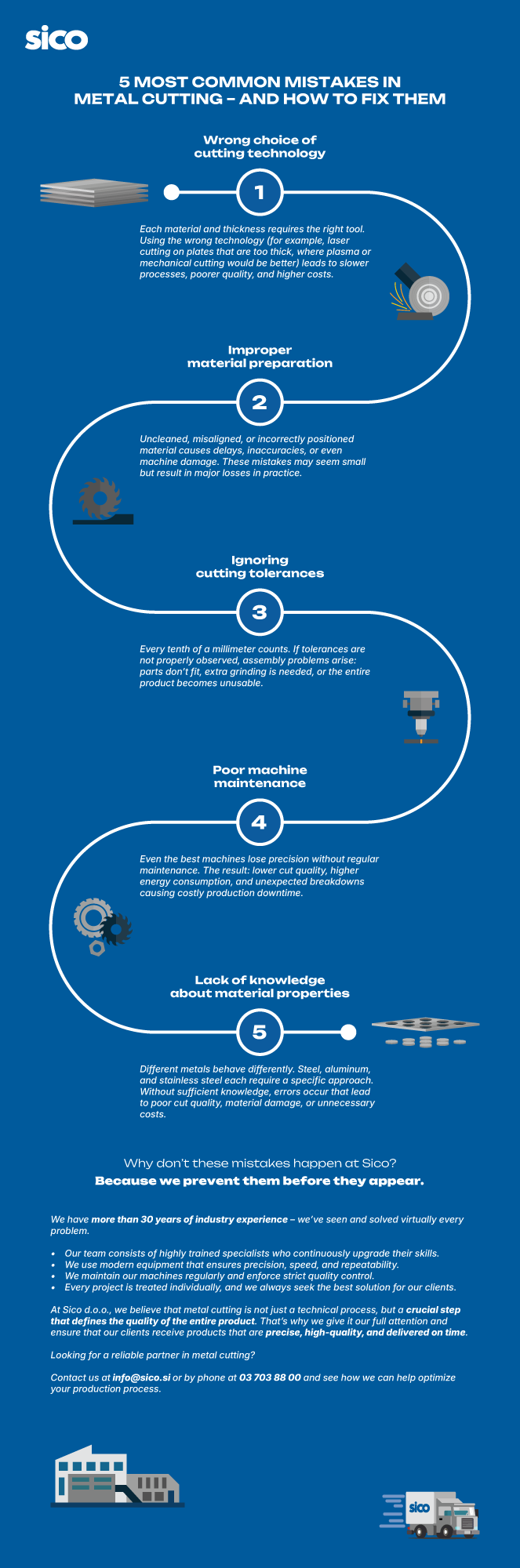

Most common 5 mistakes in metal cutting and how to avoid them

1. Wrong technology

Each material needs the right method. The wrong choice means lower quality, slower process, and higher costs.

2. Poor material preparation

If the material is dirty or misaligned, errors and delays follow.

3. Ignoring tolerances

Every fraction of a millimeter matters. Without precision, parts won’t fit.

4. Lack of maintenance

Machines without regular service lose accuracy and cause costly downtime.

5. Limited material knowledge

Steel, aluminum, and stainless require different approaches. Without expertise, mistakes happen.

At Sico, we prevent these issues with 30+ years of experience, modern equipment, skilled staff, and strict quality control.