For more than three decades, Sico d.o.o. has been investing in technologies that enable even greater precision, faster production, and complete adaptability to customer requirements. One of the key technological upgrades in recent years is our advanced tube laser cutting system, which has become an indispensable part of our production process.

For more than three decades, Sico d.o.o. has been investing in technologies that enable even greater precision, faster production, and complete adaptability to customer requirements. One of the key technological upgrades in recent years is our advanced tube laser cutting system, which has become an indispensable part of our production process.

What is a Tube Laser and Why is it So Important?

A tube laser is a high-tech machine used for cutting tubes, profiles, and other hollow metal elements with a highly precise laser beam. Compared to traditional cutting methods, it provides:

-

exceptional precision in every cut, even with complex shapes,

-

clean edges without the need for additional finishing,

-

high repeatability in serial production,

-

less waste material and shorter setup times,

-

and flexibility in processing various types of materials – from steel to aluminum and stainless alloys.

Thanks to these advantages, tube lasers are used in many industries – automotive, furniture, construction, transportation, and especially in custom metal fabrication, where every fraction of a millimeter matters.

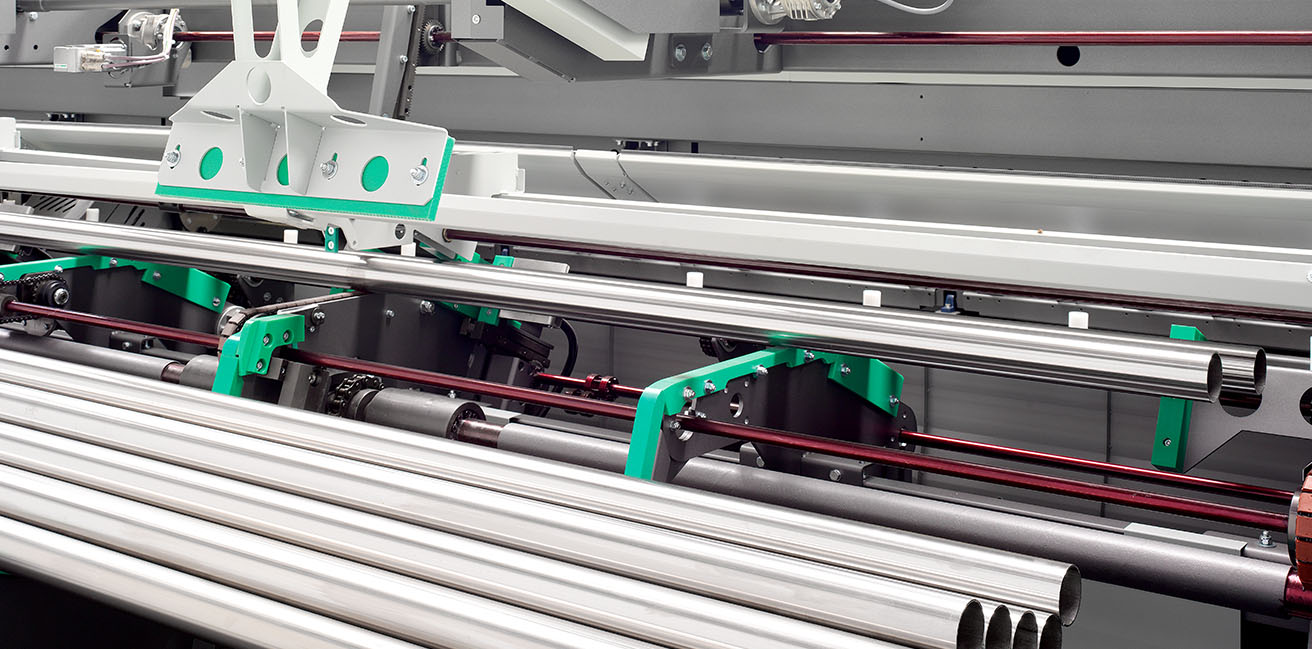

Cutting-Edge Technology – BLM Group LT8.20

Our BLM Group LT8.20 tube laser represents the top of industrial standards. Equipped with a fiber laser, it allows fast and energy-efficient processing of tubes up to 220 mm in diameter and 6.5 meters in length. The machine automatically detects the shape of the profile (round, square, rectangular, or oval) and adjusts cutting parameters according to the material and wall thickness.

Thanks to its integrated 3D cutting capabilities, we can precisely produce angled cuts, holes, openings, and clamping slots, eliminating the need for additional processing. This means your final product is ready for assembly faster, cheaper, and with higher precision.

Benefits for Our Clients

By introducing tube laser cutting, we have expanded our capabilities and increased production efficiency. For our clients, this means:

-

shorter delivery times,

-

greater flexibility for custom-made orders,

-

higher product quality and joint precision,

-

and the ability to produce complex shapes that would not be possible with traditional methods.

Every part that leaves our production line is the result of modern technology combined with decades of experience from our skilled professionals.

Sico – Your Partner for Metal Solutions of the Future

At Sico d.o.o., we believe that advanced technology also means responsibility – towards quality, the environment, and customer satisfaction. Our tube laser is part of a broader process of digitalization and automation, allowing us to remain competitive and deliver added value to our partners in Slovenia and abroad.

If you’re looking for a reliable partner for precise laser processing of tubes and metal profiles, contact us – we’ll be happy to prepare a solution tailored to your needs.